Organic fertilizer machinery plays a vital role in modern agriculture by transforming organic waste into valuable, eco-friendly fertilizer products. As global demand for sustainable farming and soil improvement continues to grow, organic fertilizer machinery has become essential for fertilizer manufacturers, agricultural enterprises, and waste recycling projects.

By using advanced organic fertilizer machinery, producers can improve production efficiency, reduce environmental pollution, and create high-quality organic fertilizers that support long-term soil health.

What Is Organic Fertilizer Machinery?

Organic fertilizer machinery refers to a complete set of equipment used to process organic raw materials into finished organic fertilizer products, usually in powder or pellet form. These machines work together to handle crushing, mixing, fermentation, pelletizing, drying, cooling, screening, and packaging.

Organic fertilizer machinery is widely used in:

- Organic fertilizer manufacturing plants

- Livestock and poultry farms

- Agricultural waste recycling facilities

- Municipal organic waste treatment projects

Raw Materials Processed by Organic Fertilizer Machinery

One of the key advantages of organic fertilizer machinery is its wide adaptability to various organic raw materials, including:

- Livestock manure (cow, chicken, pig manure)

- Compost and organic sludge

- Crop residues (straw, rice husk, corn stalks)

- Food waste and kitchen waste

- Green waste and plant residues

With proper pretreatment and fermentation, these materials can be efficiently converted into high-quality organic fertilizer.

Organic Fertilizer Production Process

A standard organic fertilizer production process using organic fertilizer machinery includes several key steps:

- Fermentation and Composting

Organic materials are fermented to kill pathogens, eliminate odors, and stabilize nutrients. - Crushing and Grinding

Fermented materials are crushed into uniform particles for further processing. - Batching and Mixing

Different materials and additives are accurately mixed to ensure balanced nutrient content. - Pelletizing or Granulation

The mixed material is formed into pellets or granules using an organic fertilizer pellet machine. - Drying and Cooling

Fertilizer pellets are dried to reduce moisture and cooled to increase strength and shelf life. - Screening and Packaging

Qualified products are screened and packaged for storage and sale.

Key Equipment Included in Organic Fertilizer Machinery

A complete set of organic fertilizer machinery typically includes:

- Compost turners or fermentation systems

- Organic fertilizer crushers and mixers

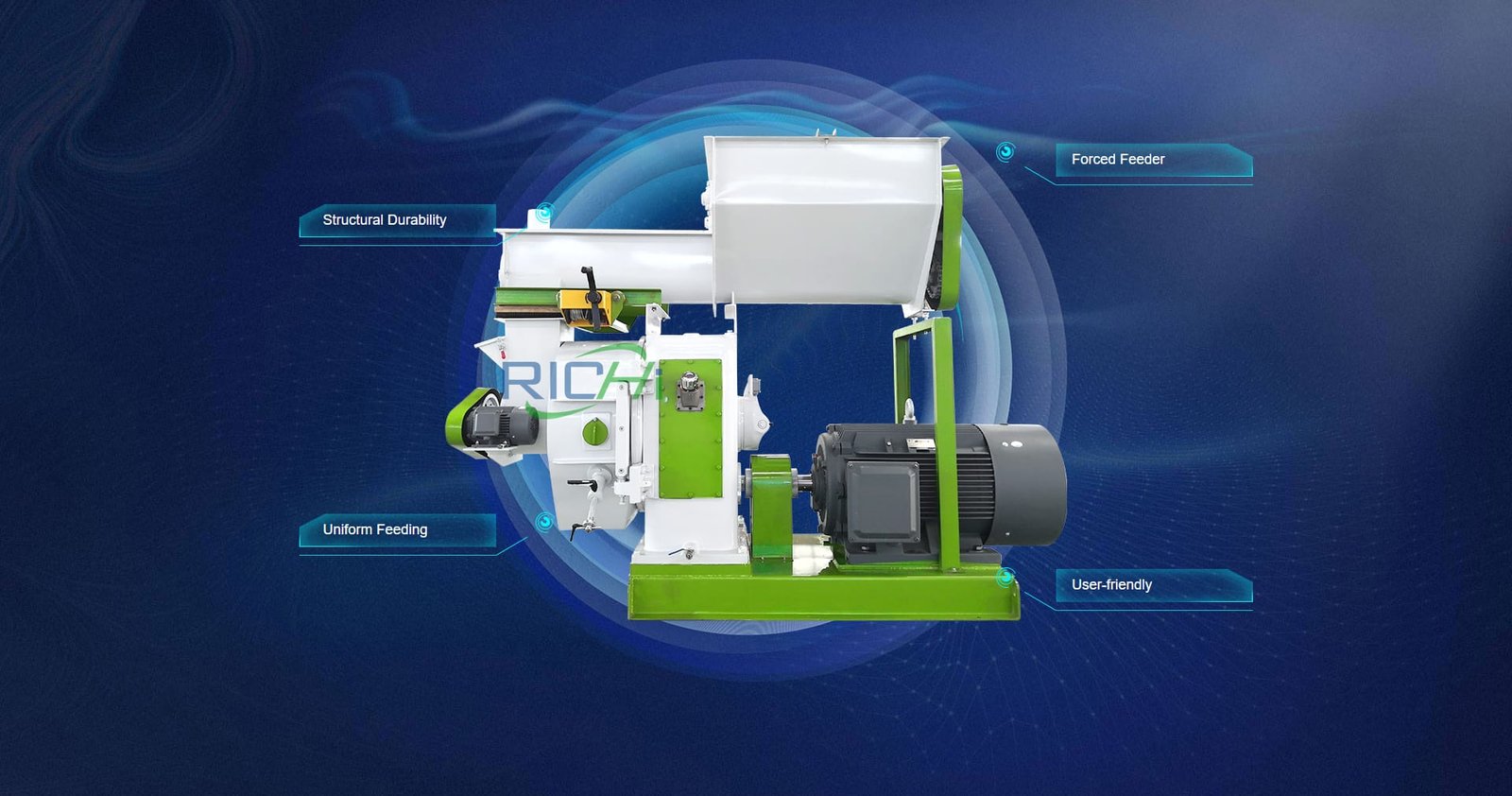

- Organic fertilizer pellet making machines

- Rotary dryers and coolers

- Screening machines

- Automatic packaging systems

Each piece of machinery is designed to ensure stable operation and consistent fertilizer quality.

Advantages of Using Organic Fertilizer Machinery

Investing in high-quality organic fertilizer machinery offers multiple benefits:

- Efficient Waste Recycling

Converts organic waste into valuable fertilizer products, reducing environmental impact. - Improved Fertilizer Quality

Uniform pellets provide better nutrient distribution and soil absorption. - High Production Efficiency

Automated systems reduce labor costs and improve consistency. - Flexible Capacity Configuration

Machinery can be customized for small, medium, or large-scale production. - Environmental Sustainability

Supports eco-friendly agriculture and circular economy development.

How to Choose the Right Organic Fertilizer Machinery

When selecting organic fertilizer machinery, consider the following factors:

Raw Material Characteristics

Moisture content, fiber level, and composition affect equipment selection.

Production Capacity Requirements

Choose machinery that matches your current needs and future expansion plans.

Level of Automation

Higher automation improves efficiency and reduces manual operation.

Energy Consumption

Energy-efficient machinery lowers operating costs and improves profitability.

Technical Support and After-Sales Service

Reliable installation guidance, training, and maintenance support are critical for long-term success.

(You can look here: https://pelletisingmachine.com/service/)

Market Demand and Applications

The global demand for organic fertilizer machinery continues to increase due to:

- Growth of organic farming and sustainable agriculture

- Rising livestock waste management requirements

- Government support for eco-friendly fertilizer production

- Increasing awareness of soil health and environmental protection

Organic fertilizers produced by organic fertilizer machinery are widely used in crop farming, horticulture, orchards, landscaping, and greenhouse cultivation.

Conclusion

Modern organic fertilizer machinery is essential for converting organic waste into high-quality fertilizer products efficiently and sustainably. With flexible configurations, reliable performance, and strong environmental benefits, organic fertilizer machinery helps producers improve profitability while supporting green agricultural development.

Choosing the right organic fertilizer machinery solution will enable you to achieve stable production, consistent quality, and long-term success in the growing organic fertilizer market.